Hi Keith,

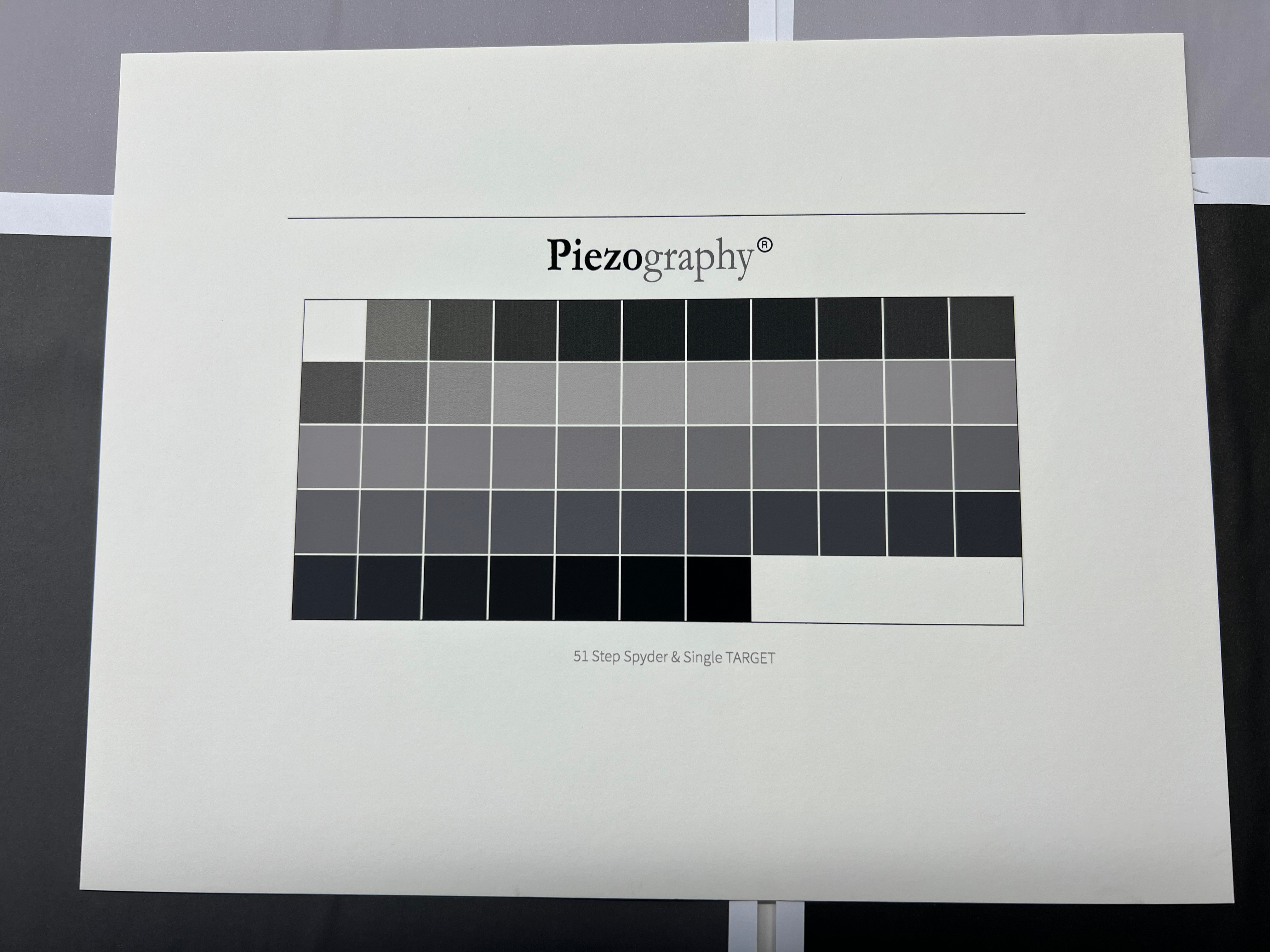

Thanks for your detailed response to my ink reversal problem. No, I’m not using any any special “infrared” ink set. Though I admit the effect is quite like infrared b+w film and it’s other-worldliness.

You’re right about the purge images. I printed them on single weight (cheap) Epson paper that wrinkled. I intended to discard them once I proved to myself that I hadn’t mixed up the ink cartridges and polluted the ink lines.

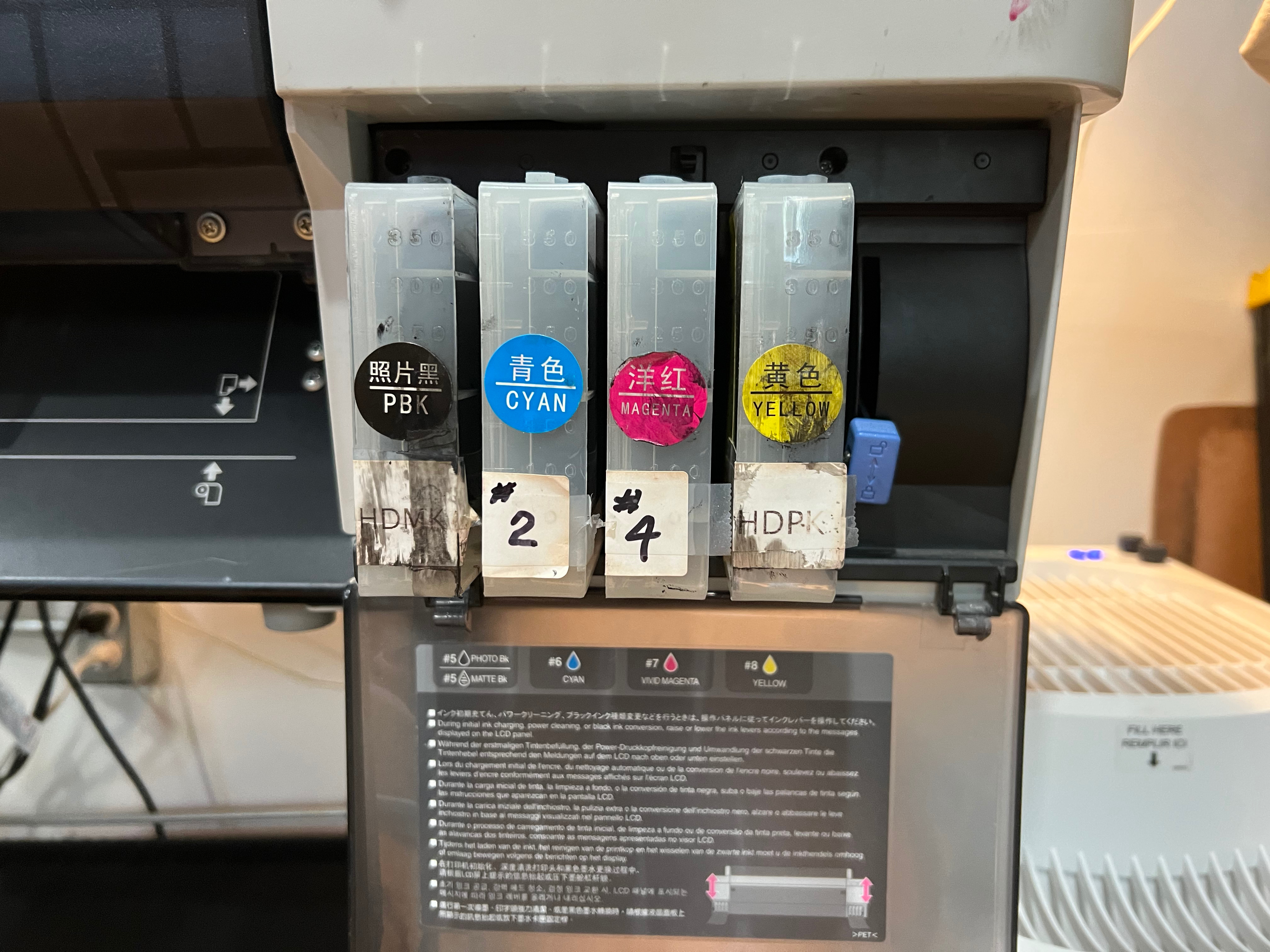

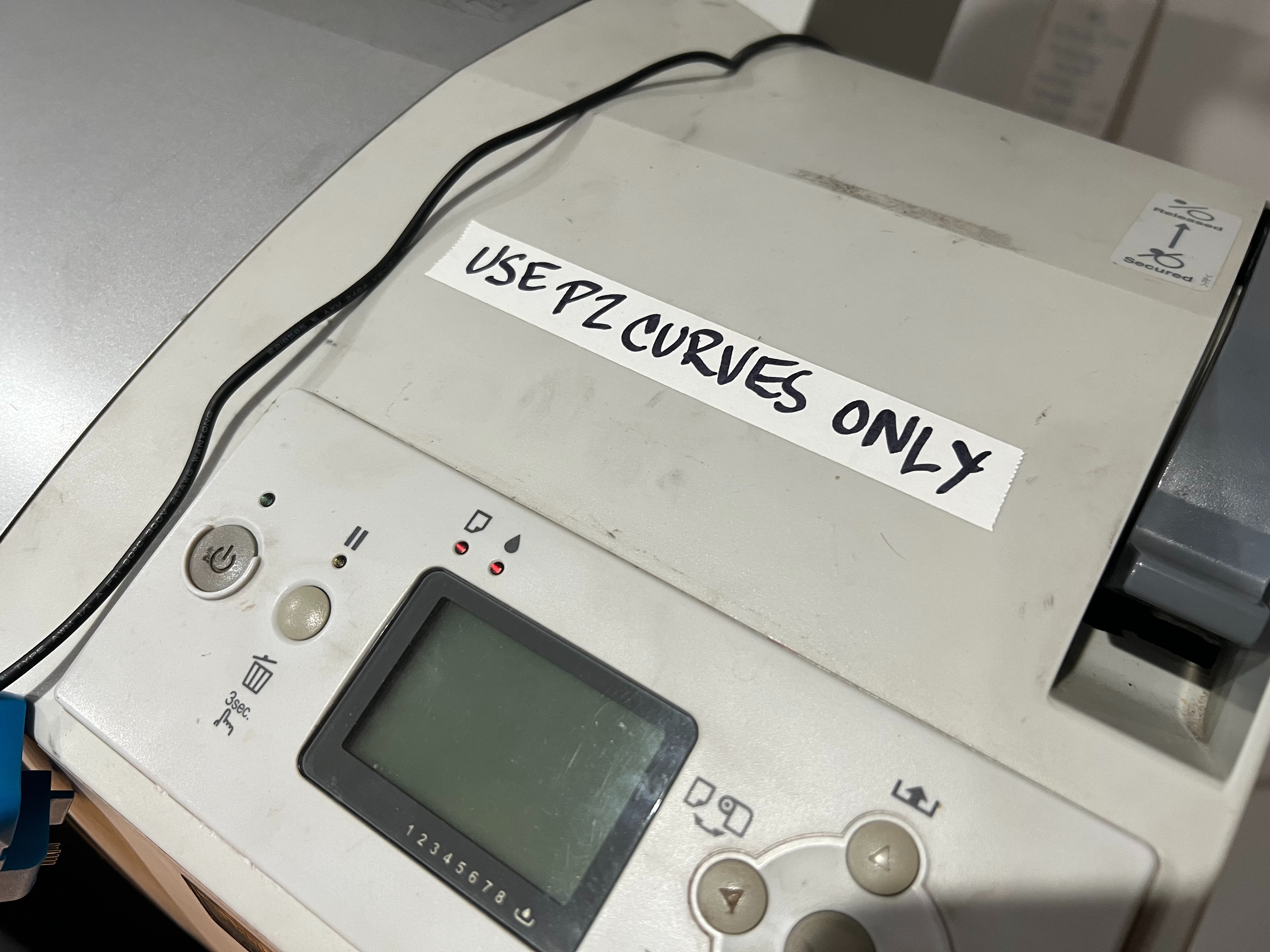

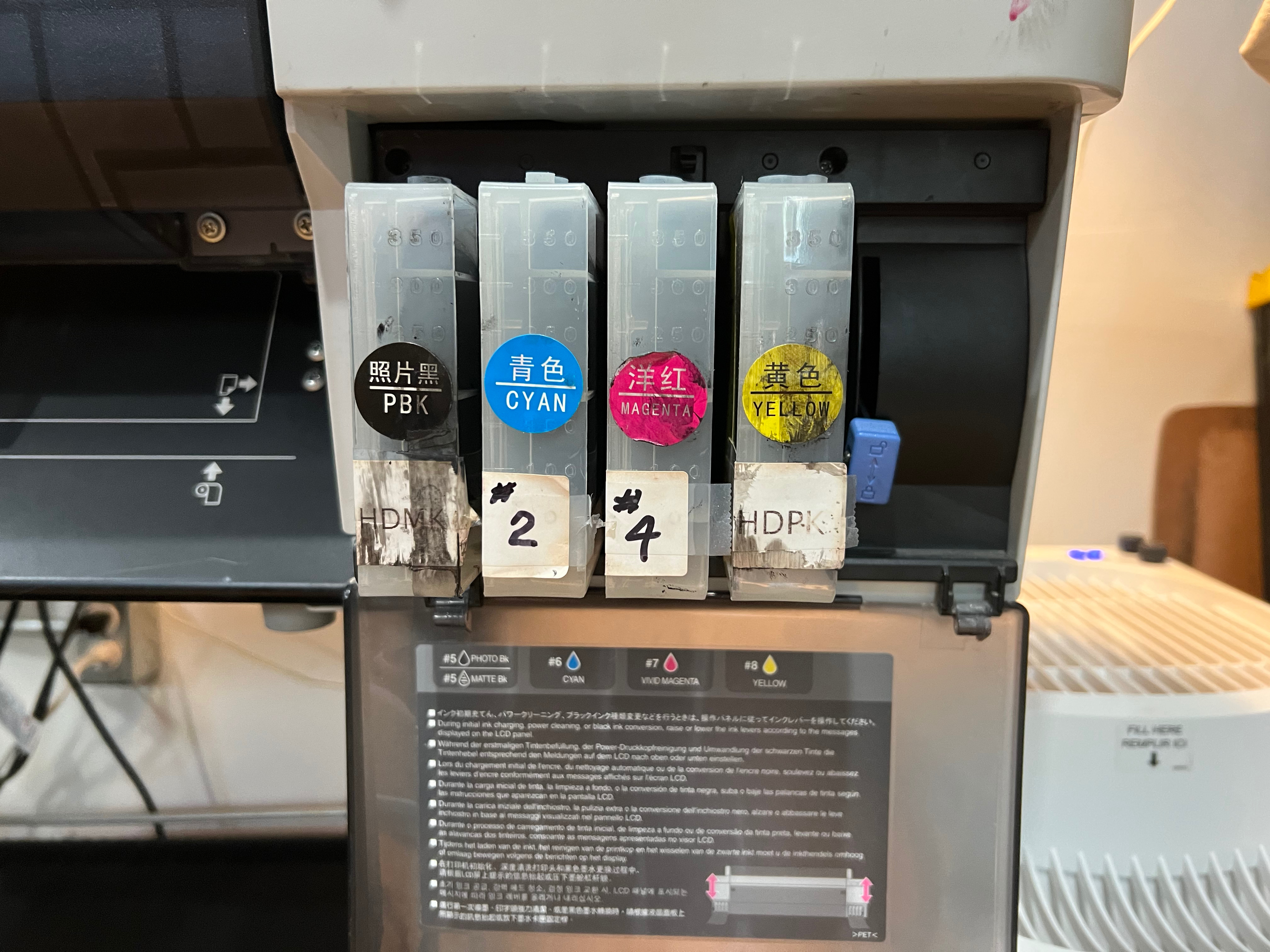

You’ll see in the accompanying photos, I have placed all the cartridges in the correct positions, although I cannot rule out an ink mis-fill, as you point out. I’m usually careful to line up the ink bottles with the corresponding carts when I refill them, but it is not impossible that I may have mixed up the inks inadvertently. I will test this hypothesis more carefully.

However, there is a more likely explanation that Walker suggested. Even though my inks are of the P2 variety, (out of sheer laziness) I was printing the images (on Cone Type2 paper) using K7-SEL-UHD-ConeType2.quad. I couldn’t find the P2 version and, instead of installing it, thought, “How much difference could there be between K7 and P2?”

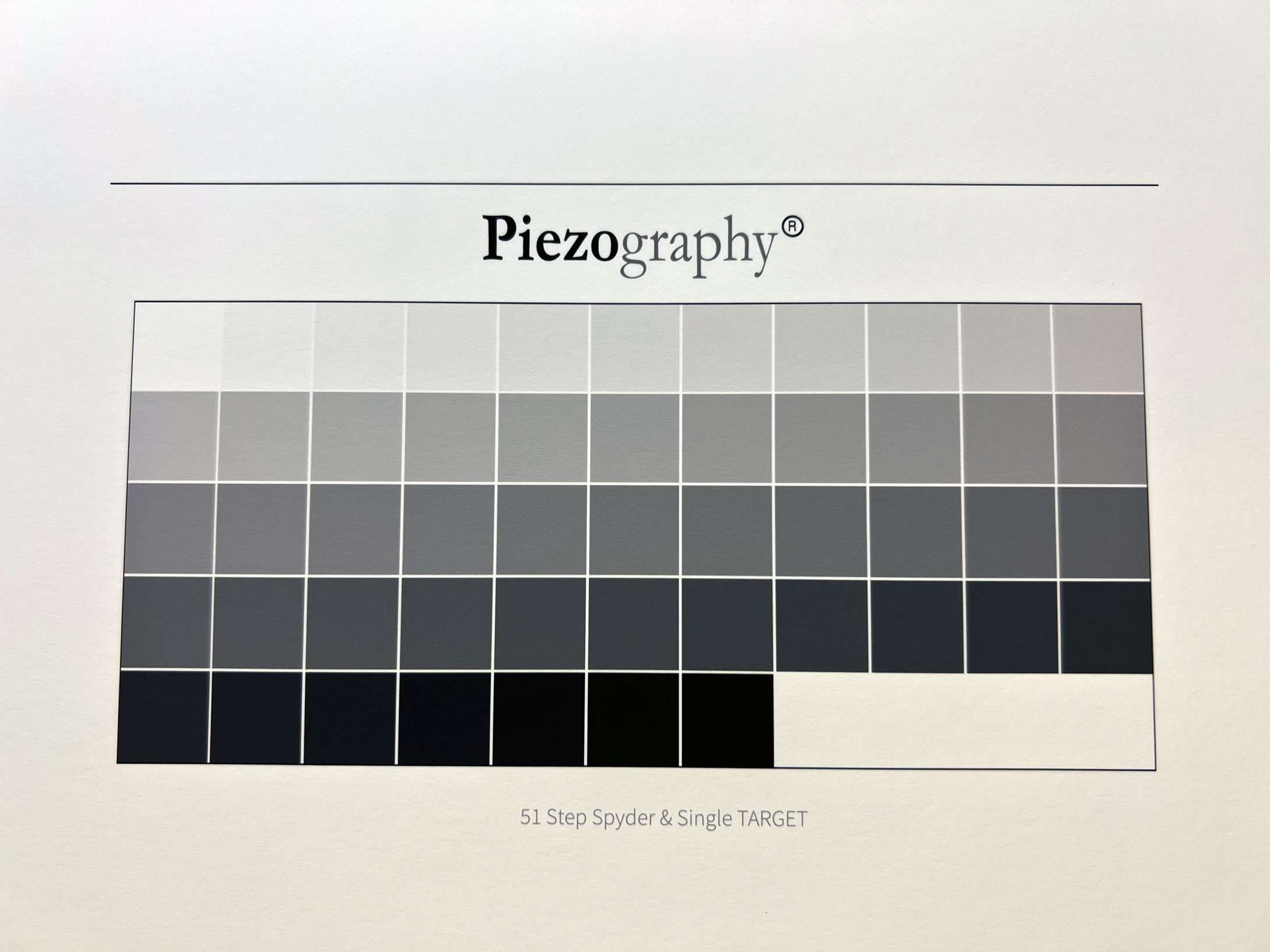

So, just now, I opened both curves in QTR-CurveView and was astonished by the Y channel output: 0 vs. 47!

I think this difference is probably the source of my problem and I will test print another set of images as soon as I return to my studio.

And now to your damper problems . . .

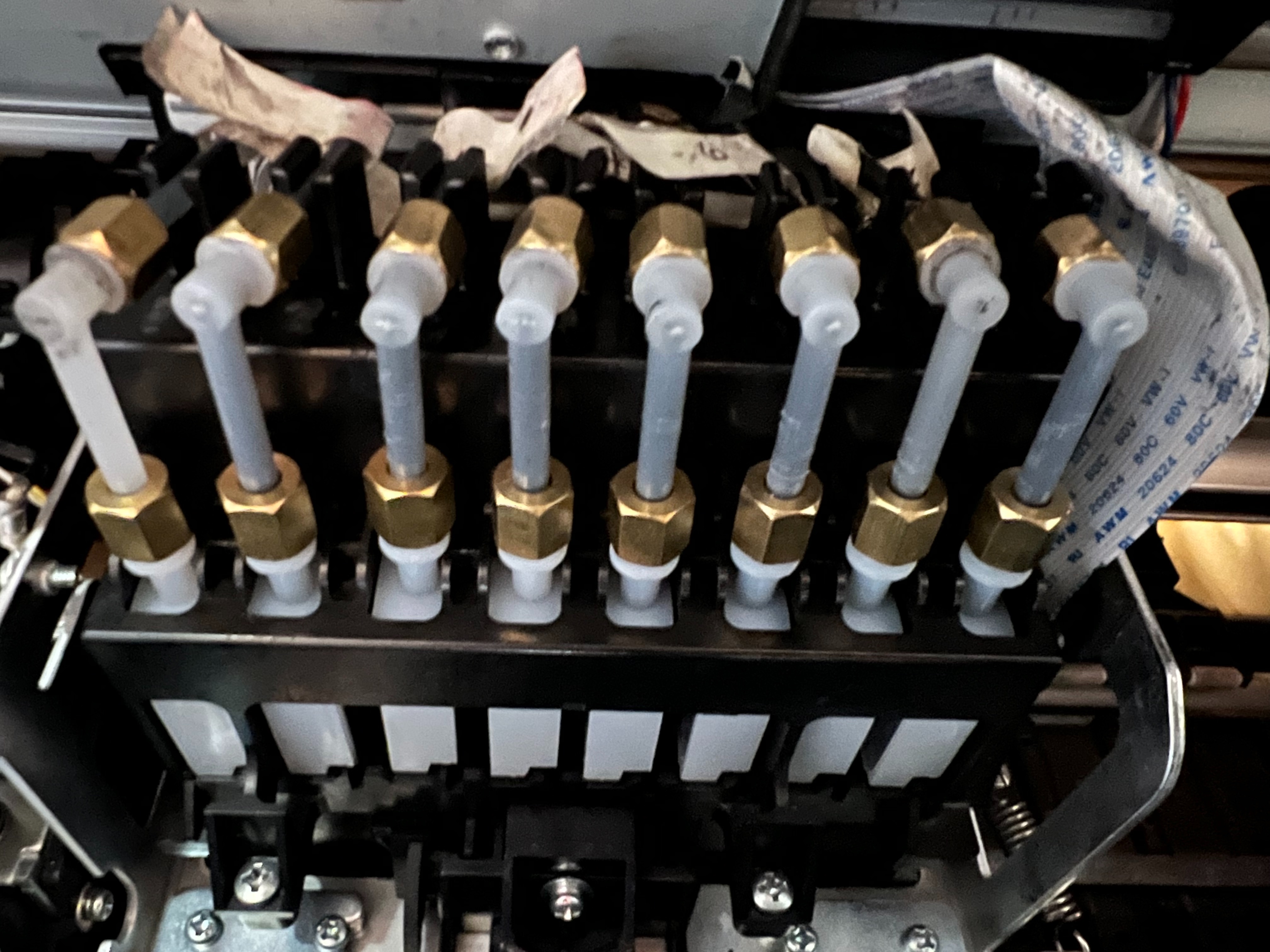

I changed all the dampers because I suspected air leaks around the O-rings were causing gaps in my nozzle test prints, not clogged printer head nozzles as is usually the case. I replaced the print head about one year ago, and was trying to figure out why my nozzle checks were failing so badly.

Since replacing the dampers, nuts, L-tubes, and O-rings, I’m finally getting perfect nozzle checks! Here are a couple of tips relating to the damper replacement procedure:

-

Get the brass nuts (sometimes listed erroneously as copper), because the plastic ones are prone to mis-threading and failure due to over-tightening. I also think they are not manufactured to exact tolerances like metal and can become distorted by heat leading to tiny air and ink leaks. A set of small open-end metric wrenches from Amazon helped me avoid over tightening and made the whole process easier.

-

The nuts and O-rings are sold in two sizes, 3.6x2.6mm (Big Damper) and 2x3mm (Small Damper); this small difference is sometimes difficult to discern and the hardware can get mixed up easily. The small nuts connect the ink supply tube to the L-shaped connecting tube. The big nut connects to the threaded nipple on the damper body. Be careful to use the correct O-ring to make an air tight seal. The small O-rings are very tiny, so make sure to order extras in case you drop one; they’re nearly impossible to find if you do! I had to use tweezers to handle them.

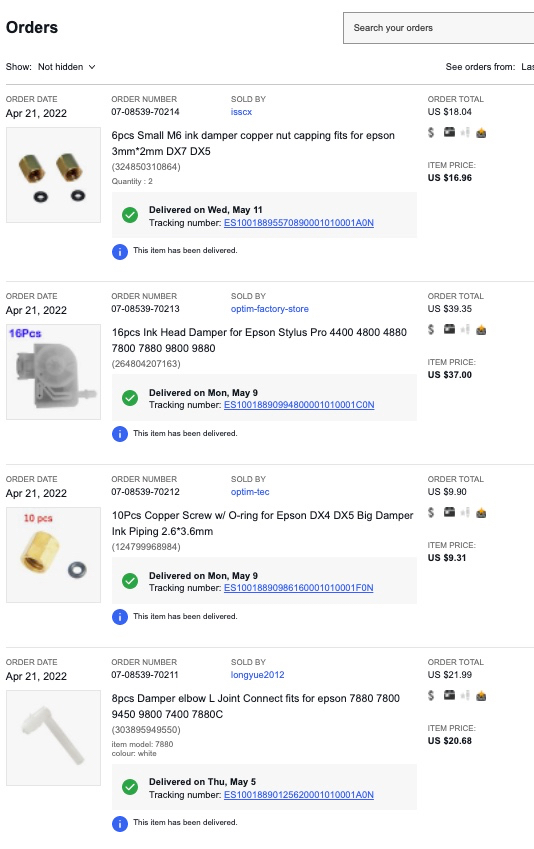

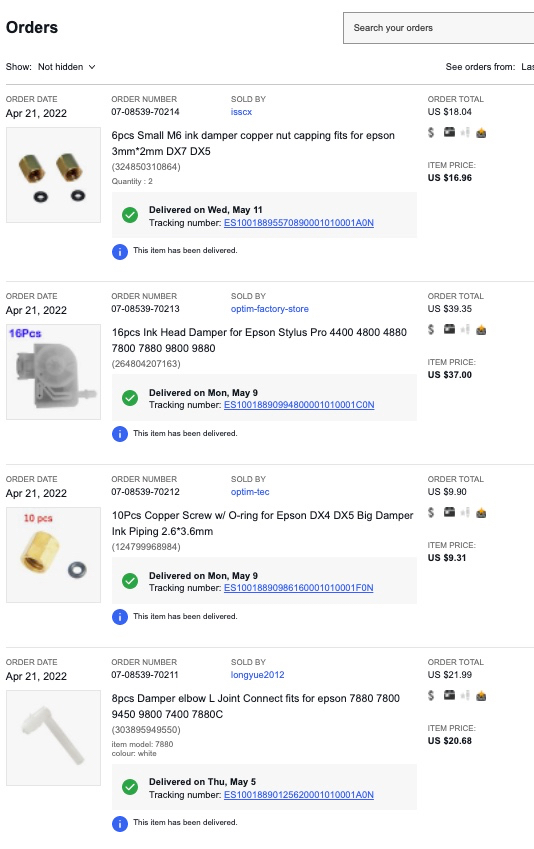

Here’s my eBay damper and nut order info. As you can see, I had four different suppliers and I waited about three weeks to receive everything. You can also find these products on Aliexpress.com but often the postage from China is four or five times the value of the product. So, I suggest looking for domestic eBay sellers who buy this stuff in bulk from China and repackage it for a profit.

Thanks again for your thoughtful comments. Hope I was able to assist in your 7880’s recovery.

–Mark